Challenge

SLR was selected to simulate air flow and leak migration patterns within our client’s compressor facility.

Solution

Using Computation Fluid Dynamic (CFD) modelling, our team accurately predicted the indoor environment of the facility. As an added level of safety, and at the request of the client, SLR simulated a variety of upset leak conditions and identified potential 'high concentration' zones of natural gas. The information was used to help improve safety protocols within the facility as well as to guide placement of added future leak sensors within the building.

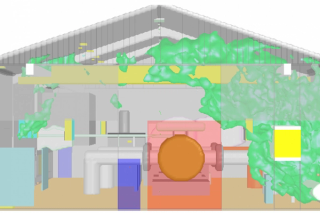

The first step required our team to build a model of the indoor environment. The model included pipes, turbines, tanks, fans, louvers, lights, building supports, exhausts, intakes and any other structures that could interfere with the room’s airflow.

With the model built, the next step was to determine the parameters of the potential leak. Working with the client, our team determined five specific scenarios to run, ranging from small leaks to larger events.

The last step was to simulate the five scenarios using CFD modelling. Model checks and sensitivity analyses were performed as part of our quality assurance processes. The simulations showed a visual representation of the leak emitted from the pipes, as well as, how the gas circulated around the environment and where high concentrations of gas built up. All scenarios were run until stabilized conditions were achieved.

Impact

The project resulted in a better understanding of high concentration zones in the event of a leak, and ultimately, a safer environment for our client and their staff.